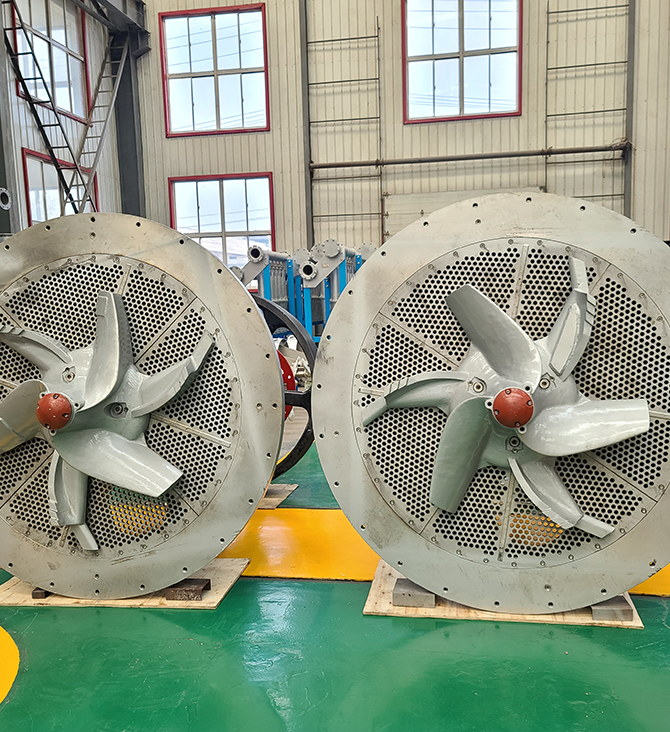

ZDSZ Series M.C. Hydrapulper

ZDSZ Series M.C. Hydrapulper is mainly applicated for separating waste paper and ink under high consistency in waste paper deinking process.

Application & Features

1. Mainly used for separating waste paper and ink under high consistency in waste paper deinking process.

2. Special spiral rotor effectively promote the circulation and rollover of pulp, reinforce friction between fibers. Finally achieve gentle pulp under high consistency, impurities will not be broke in the process of fiber relief and deinking,

3.Dealing with 12%-18% high consistency pulp, effective chemical mixture and friction between fibers under high consistency make the ink particle separate from the surface of fiber fully.

4. Compact structure, convenient operation and maintenance.

Main Specification

| Type | ZDSZ24 | ZDSZ25 | ZDSZ26 | ZDSZ27 | ZDSZ28 |

| Normal Volume(m3) | 10 | 15 | 20 | 25 | 30 |

| Consistency(%) | 5-8 | ||||

| Production capacity(t/d) | 40-60 | 60-90 | 80-120 | 120-170 | 140-190 |

| Motor power | 90 | 132 | 160 | 200 | 250 |

| Type | ZDSZ29 | ZDSZ30 | ZDSZ31 | ZDSZ32 |

| Normal Volume(m3) | 40 | 50 | 70 | 90 |

| Consistency(%) | 5-8 | |||

| Production capacity(t/d) | 220-290 | 300-400 | 450-600 | 600-800 |

| Motor power | 315 | 400 | 630 | 800 |

Download complete technical literature [PDF]

Paper pulping line requires more than guesswork.

Leizhan can offer customers complete paper pulp equipment service with rich experience. We are aiming at building a world brand in paper making & pulping field with professional skill and positive innovation spirit.

If you are interested in our products, welcome to our company, you can also consult via telephone or email. We will offer you product details and working knowledge. You will not only get high quality equipment with competitive price but also intimate service.