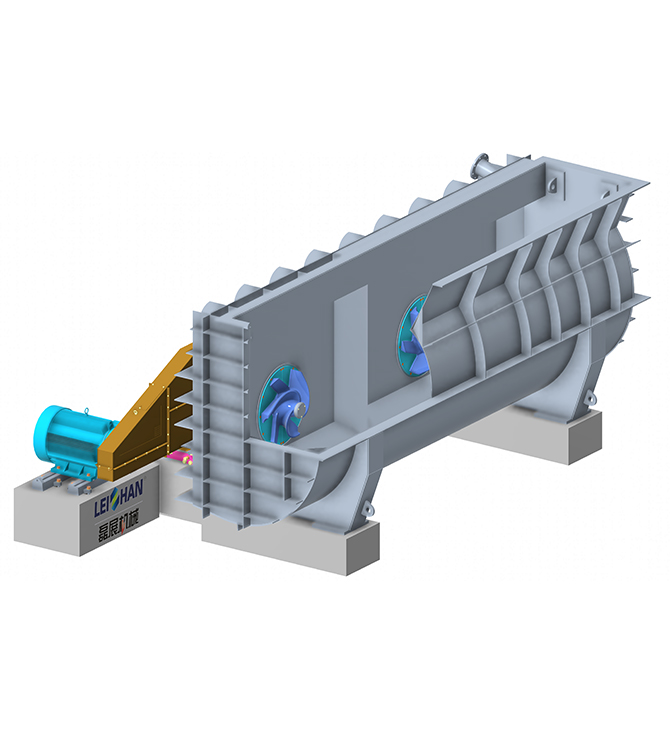

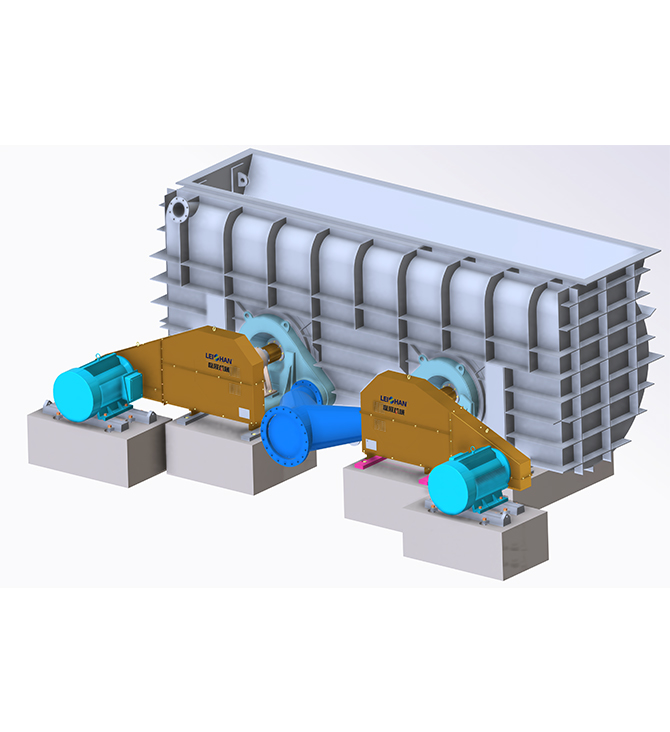

SZS Series Broken Pulper

In paper making line, our SZS series broken paper pulper can deal with the broken paper from the press part, calendering, reeling section of various kinds of paper machine for paper mill.

Application&Features

1. Mainly used for broken paper treatment from press section, calender, paper reel section, etc;

2. Optimized rotor shape for higher turbulence at the lowest consumption;

3. High pumping efficiency greatly increases the friction between the fibers – not only relying on mechanical forces between rotor and screen plate for pulp disintegration.

Main Specification

| Model | SZS1 | SZS2 | SZS3 |

| Rotor Dia.(mm) | 750 | 1000 | 1300 |

| Width of the chest(mm) | 2500-5000 | 3500-6000 | 4500-8000 |

| Pulp consistency(%) | 3-5 | ||

| Screen hole size(mm) | 10-24 | ||

| Motor power(KW) | 45-160 | 90-355 | 200-630 |

Paper pulping line requires more than guesswork.

Leizhan can offer customers complete paper pulp equipment service with rich experience. We are aiming at building a world brand in paper making & pulping field with professional skill and positive innovation spirit.

If you are interested in our products, welcome to our company, you can also consult via telephone or email. We will offer you product details and working knowledge. You will not only get high quality equipment with competitive price but also intimate service.